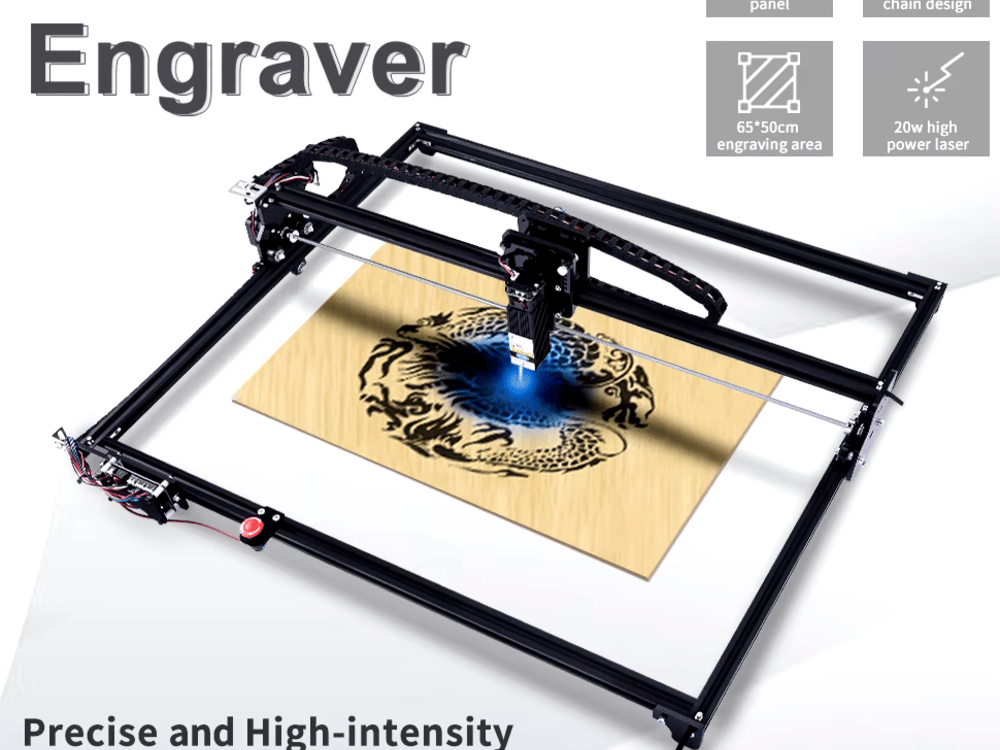

The TWOWIN Powerful Laser Engraving Machine is a high-performance CNC laser engraver featuring a robust 20W laser and a spacious 650mm x 500mm working area. Ideal for DIY enthusiasts and small business owners, this versatile machine excels in cutting and engraving a wide range of materials, including wood, acrylic, leather, and anodized aluminum. With its user-friendly design and comprehensive support, it’s perfect for both beginners and seasoned professionals looking to elevate their creative projects.

The TWOWIN 20W Laser Engraving Machine stands out as a major leap forward in desktop laser engraving technology. This powerful device blends professional precision with intuitive features that appeal to hobbyists and small business owners alike. The 20-watt laser module delivers exceptional cutting and engraving results on many materials.

Our complete review gets into the TWOWIN engraver’s performance, design features and real-life applications. You’ll find how this device works with different materials, what safety features it offers, and how it compares in value to other products in its class. We’ve included detailed test results and performance data to help you make a well-informed purchase decision.

Powerful Performance and Precision

This precision instrument features a powerful 20-watt laser module that delivers exceptional cutting performance. The machine cuts up to 25mm in pine wood and 35mm in acrylic with impressive capabilities . Its ultra-fine compressed light spot achieves remarkable precision and presents 256 different grayscale variations for detailed engraving work .

A sophisticated cooling system boosts the engraver’s performance with dual fans that reach speeds of up to 10,000 RPM, which gives it a substantial service life of 10,000 hours . The machine optimizes cutting efficiency at 2,000 millimeters per minute and achieves clean cuts through multiple passes .

The advanced color engraving capability stands out by supporting over 380 colors on stainless steel with a precise square spot size of 0.08×0.08mm . A built-in air assistance system works with a 50L air pump to reduce burn marks by 50%, which results in cleaner and more professional output .

The machine expertly handles various materials with different cutting depths:

- Pine Wood: Up to 25mm

- Acrylic: Up to 35mm

- Plywood: 10mm

- Black Acrylic: 8mm

Built-in air-guided blinds and integrated tubes boost the engraver’s precision by controlling cooling airflow. This design reduces dust accumulation on the lenses and minimizes wear and tear . Such attention to detail results in consistent performance and extended equipment life.

User-Friendly Design and Features

The TWOWIN laser engraver delivers an accessible setup and operation that works well for novices and experts alike. The machine has user-friendly software compatible with Windows XP through Windows 10 and provides free upgrades .

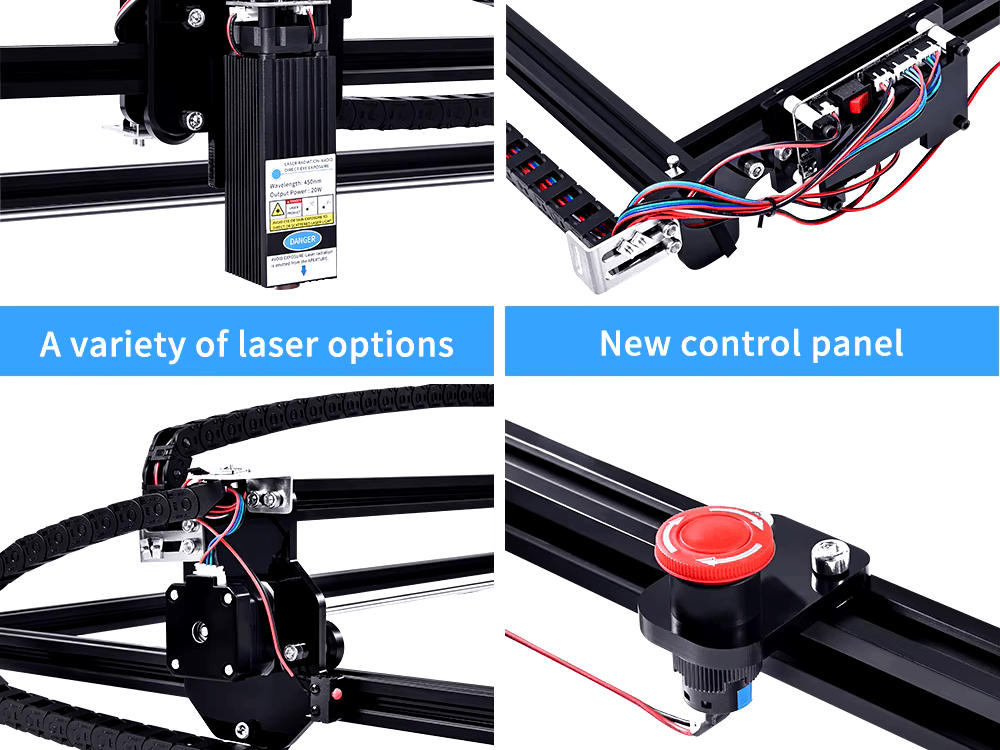

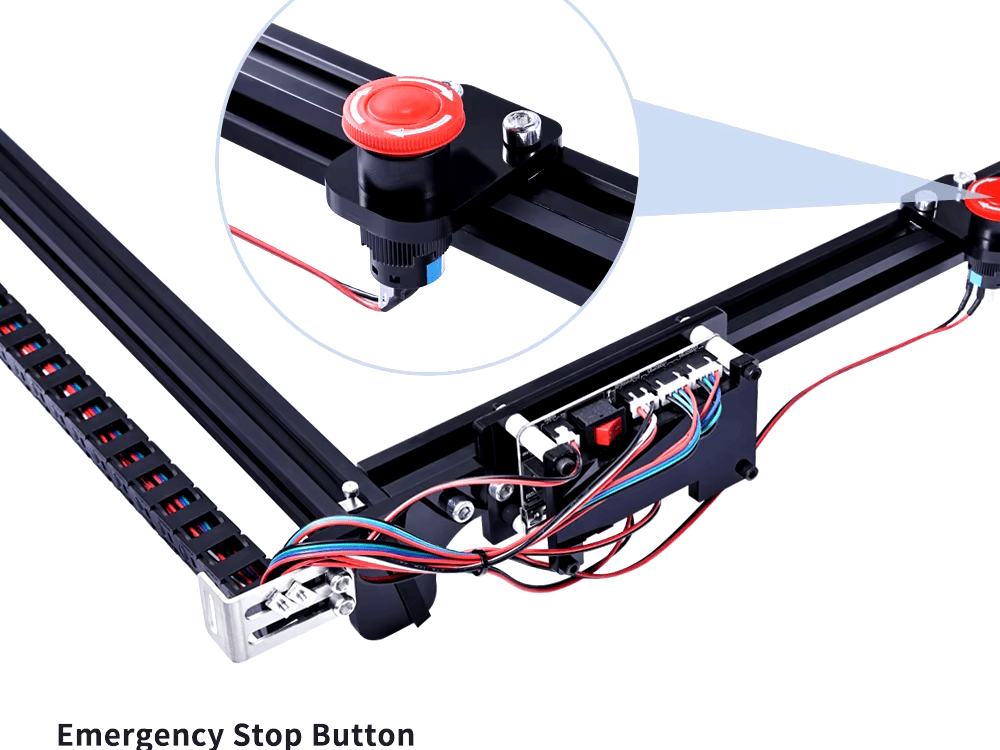

This engraver features an advanced cable management system with drag chains that keeps tubes and cables organized neatly . The motorized z-axis comes with an active probe system to automatically adjust the correct height during operations. A 5 millimeter gap between the workpiece and laser housing ensures optimal engraving distance .

The TWOWIN’s design puts safety at the vanguard with several protective features:

- Automatic shutdown upon accidental contact

- Overheating protection system

- Safe eye shielding technology

- Built-in smoke detection capability

A sophisticated air assist system with a honeycomb bed substantially enhances cut quality and keeps operations clean. The honeycomb design has convenient hold-down buttons and an aluminum base plate to protect surfaces and maintain proper airflow . Users can achieve consistent accuracy in cutting and engraving tasks through precise adjustment capabilities with grub screws .

Versatility and Applications

The TWOWIN laser engraver shines with its versatility and works with a variety of materials. This machine handles different substrates with impressive results, especially:

- Hardwood and bamboo

- Plastic and acrylic

- Leather and fabric

- Paper and cardboard

- Rubber and soft materials

Creative professionals and hobbyists will appreciate how this engraver creates detailed 3D and gradient effects on soft materials . The machine’s precision delivers beautiful results on custom items like phone shells, business cards, wallets, and rubber stamps .

A generous workspace of 40cm x 50cm (15.7 inches x 19.7 inches) gives you plenty of room to tackle both small projects and larger commercial work . Small businesses and home workshops benefit from this flexibility and professional-grade features .

Note that the TWOWIN has specific material restrictions. The machine won’t work with metals (whatever the thickness), stone, ceramics, jewelry, or transparent and reflective materials . Understanding these limitations helps you plan your projects better and choose the right materials for success.

Value for Money and Final Verdict

The TWOWIN laser engraver stands competitively in the market with prices between $108.79 to $192.99 . A comparison of cost-to-performance ratios shows the machine’s impressive value, especially with its cutting speed of 200 millimeters per minute at its power rating .

The machine comes with a simple software interface that supports JPEG, BMP, DXF, and G-code formats . Users should know that material presets aren’t included, so some experimentation is needed for optimal results . The engraver operates at remarkable speeds, but safety features need careful attention .

Buyers should think over these limitations:

- No built-in camera to line up work precisely

- Simple exhaust system

- Limited material thickness capability

- Minimal safety features

The engraver achieves an impressive accuracy of 0.05 millimeters that makes it perfect for detailed work. Standard aluminum extrusions in the machine’s construction allow future modifications and upgrades , which adds value to the original investment.

Compared to higher-end models that cost over $1,500, the TWOWIN gives great value to small businesses and hobbyists on a budget . The machine’s large working area and versatile material compatibility make its performance-to-price ratio even more attractive .

Conclusion

The TWOWIN 20W Laser Engraving Machine represents a breakthrough in desktop laser technology that combines professional-grade features with practical functionality. The powerful 20-watt laser module cuts materials with precision, and its advanced cooling systems ensure safe, reliable operation. A spacious working area and user-friendly controls make this machine valuable for creative projects and commercial use. Users should be aware that it cannot handle metals and ceramics effectively.

This laser engraver offers excellent value by balancing performance with cost. Its versatile capabilities appeal to small business owners and hobbyists who need to create intricate designs on soft materials or make deep cuts in wood and acrylic. The machine may lack some premium features, but its strong performance-to-price ratio and upgrade potential make it an excellent choice for anyone who needs professional-grade engraving without significant investment.

Frequently Asked Questions (FAQ)

Users can realize their laser engraver’s full potential and avoid common mistakes by understanding these frequently asked questions about laser engraving systems:

Does a laser engraver require constant internet connectivity? Laser engravers work independently with their internal controls for daily operations. The machine needs internet access only for software updates and remote support .

How often should the lens be cleaned? The lens’s condition is vital since smoke and residue buildup can weaken laser strength and damage it over time . Users must remove the laser from the frame, take apart the safety cover, and clean all components with isopropyl alcohol .

What should users check when experiencing power issues? Power-related problems require users to:

- Check if power cables are securely connected

- Match power supply specifications to the machine

- Examine stepper motor pulley set screws

- Use appropriate speed settings that prevent motor skipping

How can fume extraction be optimized? The best fume management combines air assist with an extraction system. Users should connect an extraction tube to a HEPA-filtered vacuum system, though the workspace might retain minimal odor .

What causes connection problems with the laser? COM port changes create most connection problems. Users should check their control software’s port assignment after powering on the laser and connecting it through USB .